描述

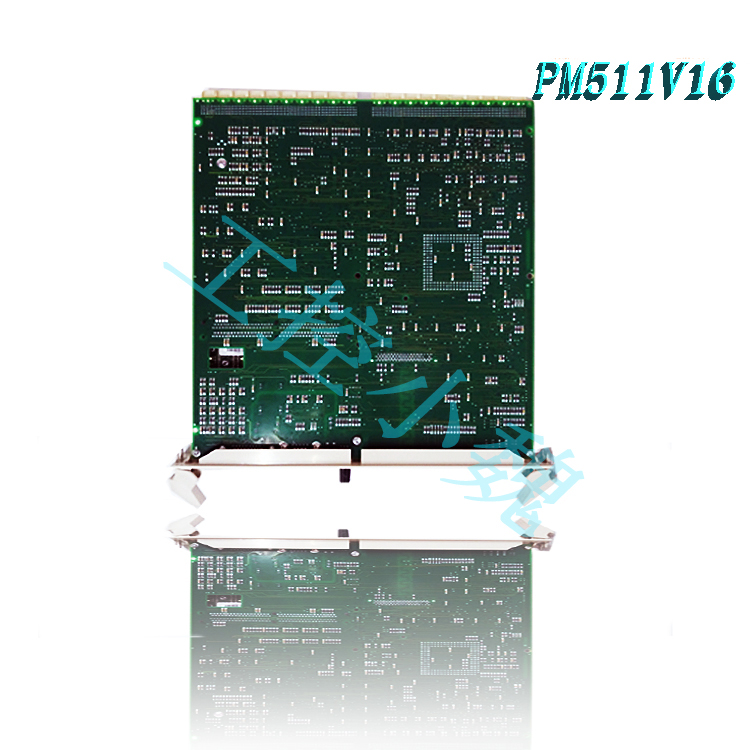

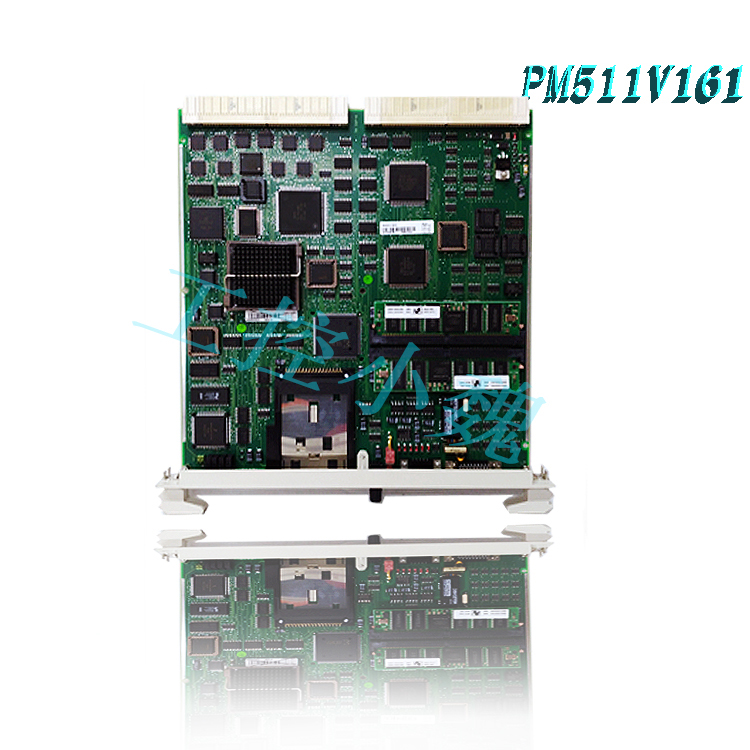

PM511V16 3BSE011181R1是一種處理器模塊,通常用于工業(yè)自動化和控制系統(tǒng)中,以執(zhí)行各種控制和數(shù)據(jù)處理任務(wù)。這種處理器模塊由ABB公司制造,并廣泛應(yīng)用于各種工業(yè)環(huán)境中。它具有強大的計算和邏輯處理能力,能夠處理各種復(fù)雜的控制系統(tǒng)任務(wù)。該模塊通常與其它工業(yè)自動化設(shè)備一起使用,如傳感器、執(zhí)行器、PLC等,以實現(xiàn)整個工業(yè)過程的自動化控制。

Millmate 控制器 400PFXA401

Millmate 控制器 400 的設(shè)計旨在提供大量功能,同時具有高度的用戶友好性。

控制單元涵蓋所有邊緣傳感器安裝可能性。這意味著用戶只需遵循分步說明即可設(shè)置控制單元并計算出正確的帶材邊緣和中心位置以及寬度。

計算相對于軋機的真實帶材位置和寬度 過濾時間 10 毫秒起 易于配置的模擬/數(shù)字輸入/輸出 數(shù)字邊緣位置液位檢測器 數(shù)字最小值 和最大。寬度水平檢測器 單位選擇(毫米、英寸) 自診斷測試系統(tǒng),包括連續(xù)邊緣傳感器測試 仿真模式方便檢查系統(tǒng)集成大型枕頭墊張緊度計冷軋機中的(LPBT) “張力控制是最重要的中的重要過程參數(shù)工藝線。為了達到好張力控制您需要可靠的輸入實際張力。因此選擇可靠的張力稱重傳感器關(guān)鍵的Gr?nges的選擇是ABB 大型枕頭墊張緊度計和 Pressductor?底層技術(shù)。壓力管道徑向張力計(PRT)在冷軋機和工藝生產(chǎn)線 PRT系統(tǒng)是一種高質(zhì)量的系統(tǒng),可通過安裝在軸上的測壓元件測量張力以及持久的性能。 PRT稱重傳感器和張力電子設(shè)備設(shè)計用于中等張力和用于光的光張力工藝線軌距和環(huán)形縱切機。易于安裝且?guī)缀鯚o需維護,PRT張力測量使對更多的重大貢獻生產(chǎn)操作和改進在產(chǎn)品質(zhì)量方面http://www.dtxgl.net/

Millmate條形掃描儀系統(tǒng)在冷軋機中 “Millmate條形掃描儀系統(tǒng)(MSS)一直在工作,MSSsensors一直在完美運行經(jīng)過多年的運營。有無需維護和保養(yǎng) MSS的成本。 MSS與傳感器一樣非常可靠不受工廠環(huán)境的影響,以及測量結(jié)果非常穩(wěn)定。卷取機對中非常好 MSS。同樣出色的反沖伸縮等缺陷。”

PM511V16 3BSE011181R1 is a processor module commonly used in industrial automation and control systems to perform various control and data processing tasks. This processor module is manufactured by ABB and widely used in various industrial environments. It has powerful computing and logical processing capabilities and can handle various complex control system tasks. This module is typically used in conjunction with other industrial automation equipment, such as sensors, actuators, PLCs, etc., to achieve automated control of the entire industrial process.

Millmate controller 400PFXA401

The design of the Millmate controller 400 is aimed at providing a wide range of features while also being highly user-friendly.

The control unit covers all installation possibilities of edge sensors. This means that users only need to follow the step-by-step instructions to set up the control unit and calculate the correct strip edge and center position as well as width.

Calculate the minimum and maximum digital values of the analog/digital input/output digital edge position liquid level detector that are easy to configure, starting from 10 milliseconds of filtering time relative to the actual strip position and width of the rolling mill. Width level detector unit selection (millimeters, inches) self diagnostic testing system, Including continuous edge sensor testing simulation mode for easy inspection of system integration, large pillow cushion tension gauge (LPBT) in cold rolling mill. “Tension control is the most important process parameter in the process line. To achieve good tension control, you need reliable input of actual tension. Therefore, the key Gr ? nges selection for selecting a reliable tension weighing sensor is ABB large pillow cushion tension gauge and Pressconductor.” ? Underlying technology. The pressure pipeline radial tension gauge (PRT) is a high-quality system used in cold rolling mills and process production line PRT systems, which can measure tension and long-lasting performance through pressure measuring elements installed on the shaft. The PRT weighing sensor and tension electronic equipment are designed for medium tension and light tension process line gauge and circular slitting machine. Easy to install and almost maintenance free, PRT tension measurement enables significant contributions to production operations and improvements in product quality

The Millmate bar scanner system is used in cold rolling mills. “The Millmate bar scanner system (MSS) has been working continuously, and MSSsensors have been operating perfectly for many years. There is no need for maintenance or upkeep of the MSS. The MSS, like sensors, is very reliable and not affected by the factory environment, and the measurement results are very stable. The coiler aligns very well with the MSS. It also has outstanding defects such as recoil and expansion.”

倉庫優(yōu)惠型號推薦: